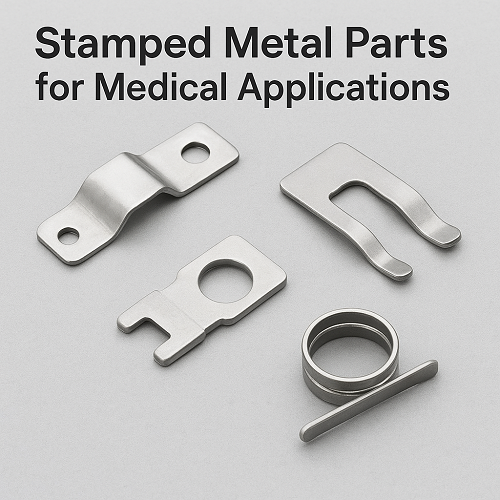

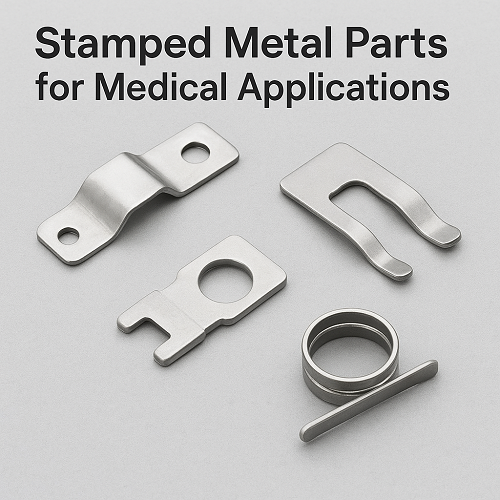

In the rapidly evolving medical industry, precision and reliability are critical. At Acro Metal Products Ltd., we specialize in manufacturing high-quality stamped metal parts designed specifically for medical applications. Our components are engineered to meet the most stringent standards, ensuring safety, durability, and consistent performance in medical devices and equipment.

Product Functions and Uses

Stamped metal parts are essential components in a wide range of medical devices and systems.

They perform critical functions such as:

- Structural Support: Providing stability and framework for medical equipment, including diagnostic machines and surgical instruments.

- Electrical Conductivity: Serving as connectors, terminals, and contacts in medical electronic devices.

- Mechanical Functionality: Acting as springs, clips, and fasteners to enable precise mechanical movements in devices like infusion pumps and prosthetics.

- Fluid and Gas Control: Used in valves and tubing connectors for controlling the flow of medical gases and liquids.

These versatile components are found in surgical instruments, diagnostic equipment, implantable devices, patient monitoring systems, and other essential healthcare tools.

Product Features

Our stamped metal parts are engineered with a focus on quality and performance.

Key features include:

- High Precision Manufacturing: Tight tolerances ensure reliable fit and function in sensitive medical applications.

- Durable Materials: We use biocompatible metals such as stainless steel, titanium, and nickel alloys to meet medical safety standards.

- Corrosion Resistance: All parts are treated to withstand sterilization processes and exposure to bodily fluids.

- Consistency and Repeatability: Advanced stamping technology ensures uniformity across production batches.

- Customizable Design: Components can be tailored to meet specific device requirements or OEM specifications.

Product Specifications

While specifications vary depending on the application, our stamped metal parts typically include:

- Material Options: Stainless steel (304, 316), titanium, nickel alloys, and specialty medical-grade metals.

- Thickness Range: 0.05 mm – 3 mm (customizable).

- Dimensional Tolerance: ±0.01 mm for critical components.

- Surface Finish: Polished, passivated, or coated to prevent corrosion and ensure biocompatibility.

- Hardness Range: HRC 20–50 depending on material and application requirements.

We can also produce intricate geometries, fine holes, and complex bends, meeting the demanding needs of medical devices.

User Manual

To ensure optimal performance, it is important to handle stamped metal parts correctly:

- Storage: Keep parts in a clean, dry environment to prevent contamination and corrosion.

- Handling: Always wear gloves when handling to prevent oils or residues from affecting surfaces.

- Inspection: Check for visible defects, burrs, or deformations before assembly.

- Cleaning: Use appropriate sterilization or cleaning processes compatible with the metal type.

- Compatibility: Ensure that parts are used in conjunction with approved devices and components.

Installation Process

Proper installation of stamped metal parts is essential for device performance:

- Preparation: Verify that the parts match the device specifications and are free from defects.

- Alignment: Position the component accurately according to the device assembly diagram.

- Securing: Use screws, clips, or other fastening methods recommended by the device manufacturer.

- Testing: Conduct functional checks to ensure proper mechanical or electrical performance.

- Final Inspection: Confirm that the installed part maintains the integrity of the device and does not interfere with other components.

For more complex assemblies, our technical team can provide guidance on best practices for installation and integration.

Stamped metal parts play a vital role in the medical industry, offering precision, durability, and reliability. At [Your Company Name], we are committed to delivering high-quality components that meet the rigorous demands of healthcare applications. From surgical instruments to diagnostic devices, our products are designed to ensure the safety, efficiency, and longevity of medical equipment.