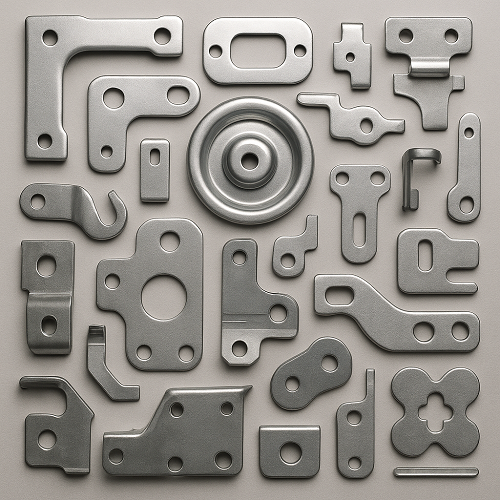

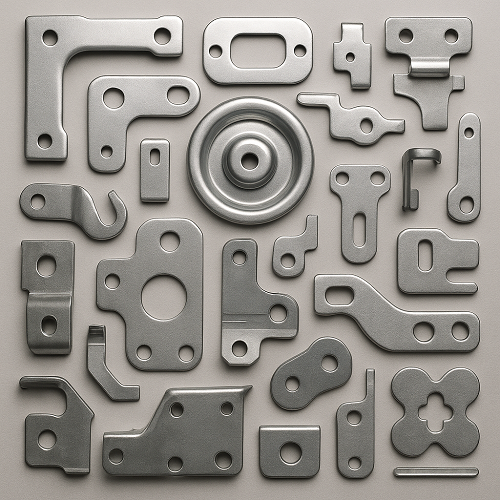

Metal stamping is a cold-forming manufacturing process that utilizes specialized dies and stamping presses to transform sheet metal into specific, often complex, shapes. It is renowned for its exceptional efficiency, repeatability, and cost-effectiveness for large production runs. From the smallest electrical contact to robust automotive structural members, metal stamping is an indispensable technology.

The Metal Stamping Process: A Symphony of Precision

The process typically involves a sequence of operations, which can be combined into a single die (progressive die) or performed individually.

- Blanking: The initial step where the outer contour of the part is cut from the larger sheet metal strip.

- Punching: Creating internal features, such as holes, slots, and notches, by removing material.

- Bending: Precisely forming the metal along a linear axis to create angled or box-shaped components.

- Deep Drawing: A complex forming operation where a metal blank is radially drawn into a forming die to create hollow, cup-shaped parts like sinks or automotive oil pans.

- Coining: A high-pressure precision stamping process that compresses the metal to create very sharp and accurate features on both sides, often used for making coins or critical mechanical parts.

- Piercing: Similar to punching, but specifically focused on creating smaller, precise holes.

Key Capabilities of a Professional Stamping Provider

A world-class metal stamping partner offers more than just a press.

Their expertise is demonstrated through:

- Progressive Die Stamping: The pinnacle of efficiency for high-volume projects. A single die with multiple stations performs all operations in a continuous, automated sequence, yielding a finished part with each press stroke.

- Deep Draw Stamping: Mastery over this process allows for the production of seamless, complex geometries with excellent structural integrity and material distribution.

- High-Speed Stamping: Capabilities to run presses at extremely high speeds (hundreds of strokes per minute) for mass production, while maintaining stringent quality control.

- Secondary Operations: A full-service provider offers value-added services in-house, including:

- Deburring: Removing sharp edges for safety and functionality.

- Threading: Adding screw threads for assembly.

- Welding: Joining multiple stampings into a sub-assembly.

- Surface Finishing: Applying platings (zinc, nickel), coatings (powder coat), or treatments (anodizing) for corrosion resistance, wear resistance, and aesthetics.

Design for Manufacturability (DFM) and Material Selection

Collaboration during the design phase is critical. An experienced stamping engineer can provide DFM analysis to optimize part design for the stamping process, reducing cost and improving quality by:

- Specifying appropriate bend radii to prevent cracking.

- Ensuring tolerances are realistic and manufacturable.

- Recommending the most suitable material for the application.

Common materials include:

- Cold Rolled Steel (CRS): Excellent strength and formability.

- Aluminum: Lightweight with good corrosion resistance.

- Stainless Steel: Superior corrosion and heat resistance.

- Copper and Brass: Excellent electrical and thermal conductivity.

- High-Strength Low-Alloy (HSLA) Steels: Used in automotive for lightweight, high-strength components.

Quality Assurance and Metrology

Precision is meaningless without verification. A professional stamping facility is underpinned by a robust Quality Management System (e.g., IATF 16949 for automotive).

- Statistical Process Control (SPC): Real-time monitoring of production data to identify and correct process variations before non-conforming parts are produced.

- Advanced Metrology: Utilization of Coordinate Measuring Machines (CMM), optical comparators, and laser scanners to verify that parts conform to all critical dimensions on the design print.

- Material Certification: Sourcing raw materials from certified mills and providing full traceability.

Industry Applications

- Automotive: Structural frames, brake brackets, engine mounts, electrical connectors, and shielding.

- Electronics: EMI/RFI shielding cans, heat sinks, connector leads, and device housings.

- Aerospace: Lightweight structural components, brackets, and avionics enclosures.

- Medical: Surgical instrument components, implantable device housings, and diagnostic equipment parts.

Metal stamping is a cornerstone of modern manufacturing, enabling the high-volume production of complex, high-strength, and dimensionally stable components.